Characteristics of Reliable Rubber Injection Molding Companies / Rubber Injection Molding Companies / Rubber Injection Molding Applications and Customization Possibilities / Count on Qualiform’s Strict Quality Assurance Standards / Additional Questions

Trying to choose between rubber injection molding companies for your next project? Reach out to the team from Qualiform today to learn more.

Characteristics of Reliable Rubber Injection Molding Companies

If you and your team need custom injection molded rubber parts for your next project, then you will need to dedicate some time to researching partner businesses. When you take the time to compare rubber injection molding companies, you can benefit from the most cost-effective results possible.

For example, it is critical to compare potential collaborators’ certifications. Is a team ISO-certified? Can a company comply with FDA regulations or other standards?

You should also consider a team’s communication practices. Can you access customer service representatives easily? Is the company’s website both responsive and up to date?

Compatibility with your industry is another critical factor to consider when comparing rubber injection molding companies. Consulting online reviews can be helpful when gauging the past experiences of other companies in your field with potential collaborators.

Rubber Injection Molding Companies

Have you been looking for reliable rubber injection molding companies for your next project? If so, then reach out to the rubber fabrication experts from Qualiform today. Companies across a diverse range of industries count on the injection molding experts from Qualiform. For more than three decades, the Qualiform team has worked to both distinguish the company from competing rubber injection molding companies and earn a reputation for excellence.

OEMs from all over the United States turn to the experts from Qualiform to meet strict material requirements, design specifications and complex part geometries.

Rubber Injection Molding Applications and Customization Possibilities

Rubber injection molding has been a fabrication method of choice for numerous manufacturers since the 1960s. In fact, the method has proven useful for healthcare, electrical, plumbing, appliance manufacturing, industrial, automotive, electronics and aerospace applications as well as numerous other tasks.

Rubber injection molding can accommodate a nearly endless range of part customizations. To list, manufacturers have chosen the rubber fabrication method for boots, gaskets, seals, grommets, bumpers, grips, shock absorbers, diaphragms, bellows and more. Rubber injection molding can also accommodate products resistant to chemicals, corrosion or abrasion.

Count on Qualiform’s Strict Quality Assurance Standards

Qualiform’s ISO 9001:2015 certification tells both current and potential customers the company has met strict quality management system standards. Overall, the Qualiform team commits to producing custom rubber molded products of the highest quality while meeting the strictest standards. The professionals from Qualiform dedicate themselves to customer satisfaction, above all.

Different rubber fabrication methods are best for different tasks and environments. For this reason, Qualiform offers a diverse range of fabrication capabilities to suit a diverse range of applications. In fact, Qualiform customers can take advantage of injection molding, rubber to metal bonding and transfer molding, for example.

The professionals from Qualiform commit to helping all clients choose the most cost-effective fabrication method or methods for their tasks. Count on the team of technicians from Qualiform to collaborate with your design team to decide the ideal manufacturing processes for your needs. Overall, the professionals from Qualiform have both the experience and the problem-solving skills to take on any design challenge.

Qualiform fabricates an extensive selection of rubber materials. In fact, Qualiform customers can choose from butyl, SBR, natural rubber, silicone, colored rubber compounds, EPDM, nitrile, Viton and neoprene.

Among rubber injection molding companies, Qualiform leads the way. Customers can count on the dedicated professionals from Qualiform for fast turnarounds on all molding and rubber to metal bonding products. Through a full-service manufacturing system and a 3-shift production facility, the Qualiform team has what you need for rapid turnarounds.

In addition, customers benefit from competitive prices because the Qualiform team commits to an extensive research and development process as well as consistent monitoring of raw material costs. In all, the Qualiform team commits to offering all customers the ideal solutions at the best possible price.

Additional Questions

The technical staff from Qualiform is available to answer any questions you may have. In fact, the dedicated Qualiform customer service team offers reliable, courteous and responsible communication that includes a detail-oriented follow-up with every customer.

To reach out to Qualiform’s technical staff, simply call (330) 336-6777, or learn more by visiting the Qualiform company website.

Our technical staff is ready to assist you with all your custom rubber injection molding needs.

An example of a flexible strain relief protector.

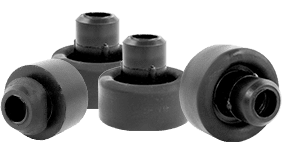

Vibration isolation grommets customized for your needs.

Specific customized rubber grommets for your needs.