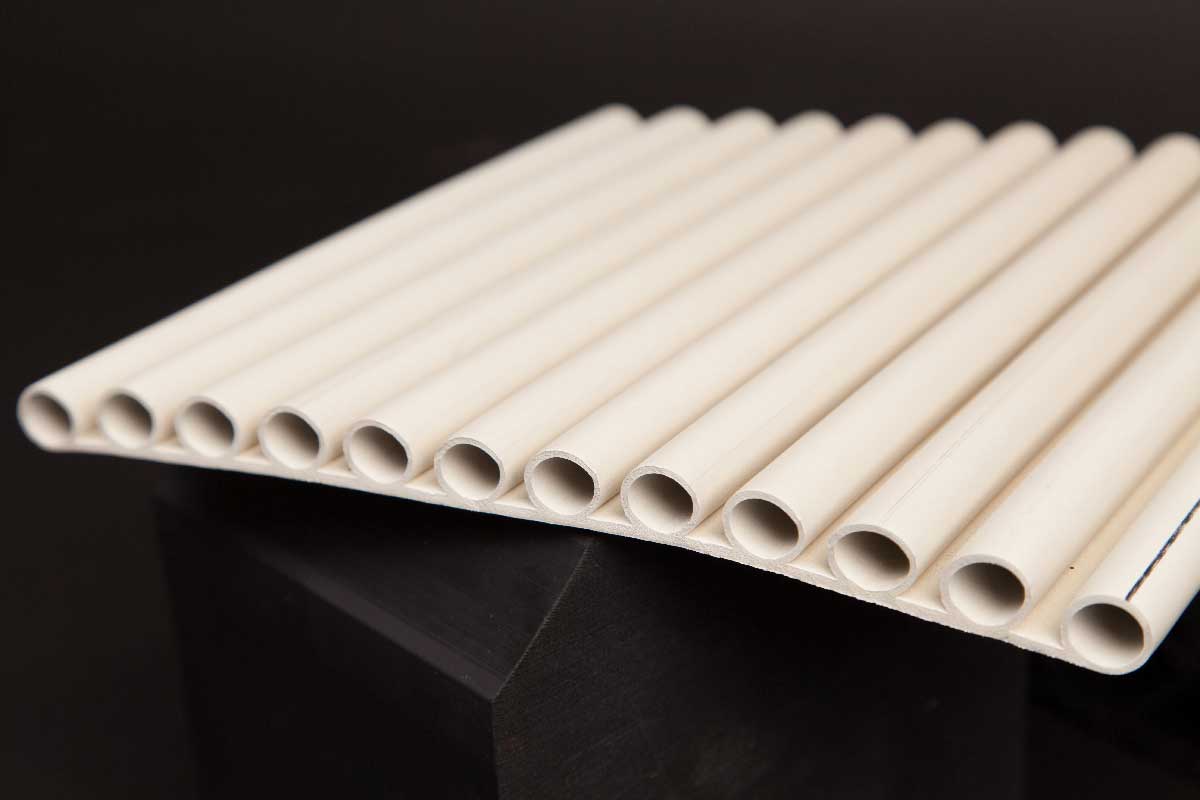

Rubber extrusions from Qualiform are available in a wide variety of shapes, sizes, and options. Each extruded rubber profile has its own unique uses and benefits. Common applications include creating seals, noise cancellation, impact absorption, vibration control, and even decorative trim for windows.

As a leading provider of custom rubber extrusion profiles, Qualiform can manufacture a wide array of extruded rubber profiles tailored to your needs. With our extensive experience and high-precision molding equipment, we can develop the perfect custom rubber profile for your specific application.

Types of Extruded Rubber Profiles

B Profile Extrusions

B profile rubber extrusions are commonly manufactured with neoprene rubber. As a result, they offer the durability and resistances necessary to perform in a wide variety of applications. Neoprene B profile extrusions also have high impact absorption properties, making them ideal for intense working environments. In fact, many naval vessels tend to use B profile marine rubber seals for marine fendering and leak prevention.

D Profile Rubber Seals

Rubber D profiles are versatile components that come in several shapes and sizes as well as rubber compounds. For example, D profile EPDM rubber offers both weathering and ozone resistance, allowing it to perform both indoors and outdoors. Natural rubber D profile extrusions, however, are designed for superior friction resistance and high tensile strength. Regardless of the rubber compound, rubber D profile extrusions have useful sealing and impact absorption properties.

E Profile Rubber Seals

E profile rubber seals are most often used as both door and window seals. The unique design of E profile extrusions allows them to latch on to window and door panels without adhesives or fasteners. They are incredibly easy to install and remove when needed. Here at Qualiform, we are able to custom design E profile extrusions with a variety of rubber compounds, so they offer superior performance for your particular application.

L Profile Extrusions

Rubber L profile extrusions offer both sealing and protective properties in many different applications. A common use of L profile extrusions is anti-slip protection. When paired with rubber floor mats, these extrusions can prevent the mat from moving as people travel over it. These profiles also provide impact resistance, making them a viable choice for protecting glass and sheet metal.

Our L profile extrusions are most often manufactured with EPDM or neoprene rubber. However, we can adapt our rubber molding process for unique compounds and dimensional requirements when necessary.

P Profile Rubber Seals

These types of extrusion profiles are incredibly versatile and are a popular sealing solution for numerous applications. You may see P profile seals referred to as P seals, rubber beading profiles, tadpole seals, piping extrusions, or P profile rubber draught seals. P profile rubber seals often come in EPDM, silicone, or thermoplastic elastomers (TPE). Depending on your application, Qualiform can custom manufacture either solid or hollow P profile seals with the ideal compounds and dimensions.

T Profile Rubber Extrusions

T profile rubber extruded profiles are characterized by their T-shaped cross-section. T profile rubber seals work as gaskets that provide both sealing and insulation. Rubber T profile extrusions are useful in industries ranging from agriculture to aerospace and can be molded with a full inventory of elastomers depending on the specific application environment.

U Profile Rubber Strips

U profile extrusions are also referred to as U rubber profile edging, U rubber trim profiles, and U profile rubber seals. Usually designed with EPDM, neoprene, and TPE, rubber U channel profiles are often used for edge trim and edge protection. Their superior flexibility and tear resistance allow them to protect glass and sheet metal panels from drops and other impacts. They also prevent any injuries that could occur due to sharp edges.

Another reason to choose rubber U channel profiles is easy installation. You can easily slide the rubber extrusion profile over whatever edge you are protecting without any adhesives. These profiles are incredibly easy to apply and reuse for multiple projects.

Picking the Right Extruded Rubber Profile

Choosing a great custom rubber profile for your project requires consideration of many factors. Most importantly, you need to choose a rubber compound that will perform perfectly for your application. Keep in mind, selecting the best materials depends on many variables.

For example, you may be considering synthetic rubber for your rubber gasket profiles. Synthetic rubber is a versatile compound offering wear, abrasion, and water resistance with the ability to handle extreme temperatures. It is also cost-effective with prices lower than natural rubber. However, if your application involves exposure to acids, oils, greases, fats, or ozone, it will not perform properly.

As America’s favorite extruded rubber profiles manufacturer, Qualiform carries a diverse selection of rubber compounds. So, we can create custom rubber profiles for virtually any project. Our rubber compounds include:

- Butyl Rubber

- EPDM Rubber

- Natural Rubber

- Neoprene Rubber

- Nitrile Rubber

- Rigid & Flexible

- Synthetic Rubber

- Thermoplastic Elastomers (TPE)

- Viton Rubber

If you are unsure of what profile or rubber compound you need, contact Qualiform today. Our technical staff is here to answer any questions you have and provide expert recommendations depending on your specific industry and application.

Applications

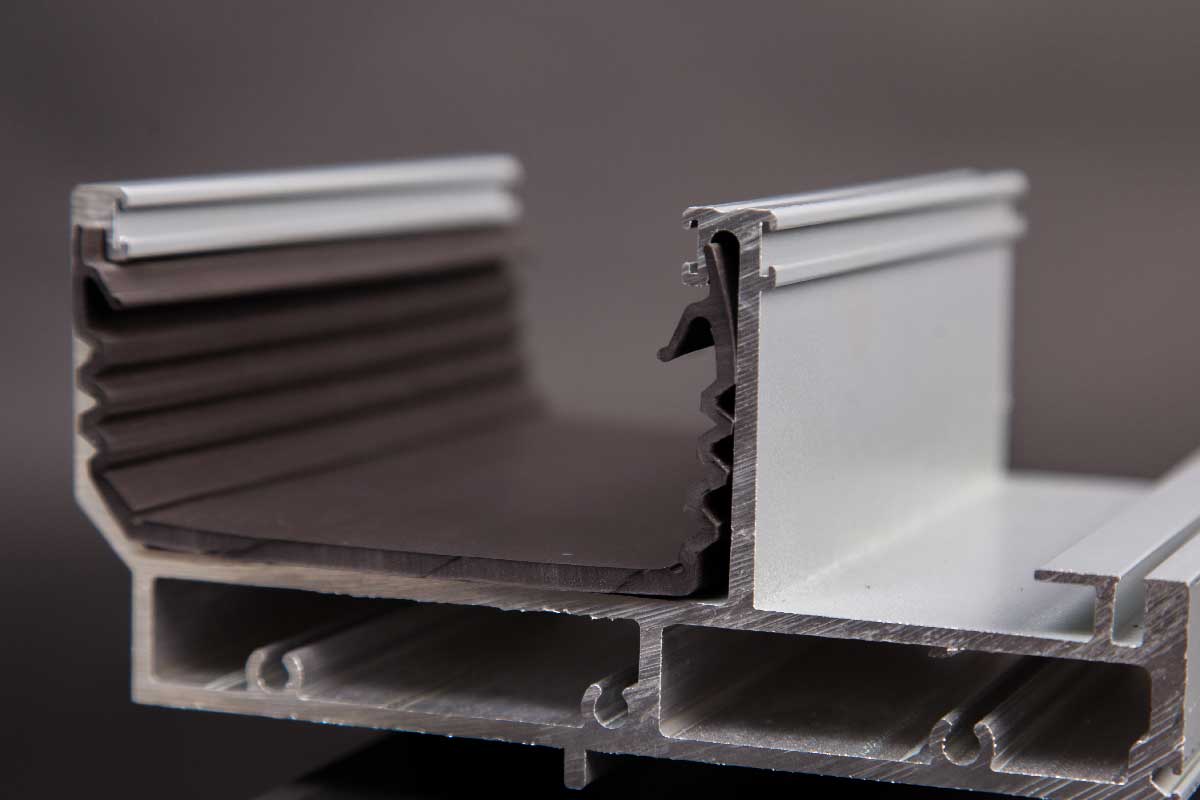

Glazing Rubber Seals We Produce

Materials Used in Rubber Extruded Products

To create a custom rubber extrusion, rubber extrusion companies think about a number of design factors, all related to the application. One of the first things considered is material. Rubber material choice depends entirely on how it will match the application requirements. Then, our rubber extrusion experts plan out the shape of the die. They may also consult their standard rubber die list, but they make new dies for our custom extrusion process.

Based on the required properties and application of the finished extrusion, Qualiform can advise on the best material for the extrusion. Additional consideration will be given to any secondary processes that are required. Custom compounds and fiber integration can be used when needed.

Natural Rubber

Natural rubber provides excellent acid, chemical, and abrasion resistance.

Silicone Rubber

Silicone rubber is an FDA-certified elastomer that maintains its form and properties when exposed to both high and low temperatures.

Viton

Viton provides superior heat, chemical, and weathering resistance.

Nitrile

Nitrile, aka nitrile rubber, NBR (nitrile butadiene rubber), acrylonitrile-butadiene rubber, Perbunan, or Buna-Nis, is highly resistant to oils and ideal for O-rings, hoses, or hydraulic seals.

Neoprene

Neoprene has high tensile strength and resists heat, fire, UV rays, water, and oil.

Butyl

Butyl delivers low airflow permeability.

SBR

SBR (styrene-butadiene rubber) is used in applications that require high abrasion resistance.

EPDM

EPDM (ethylene propylene diene terpolymer) is ideal for applications that involve heat, aging, ozone, oxidation, and ultraviolet rays. Can be used for sponge rubber, foam rubber, weather-stripping, tarp straps, door gaskets, window gaskets, and roofing membrane.

Benefits of Buying Rubber Extrusions

There are many reasons to choose rubber extrusions from Qualiform. First, it offers great freedom of design. You can request parts in nearly shape and size, and rubber extrusion companies can use nearly any rubber material. This means that you also have many choices when it comes to the qualities your part will exude. Another great benefit of rubber extrusion is that it makes parts that are both strong and flexible and soft.

Have any questions about our services? Call us at (330) 336-6777 or submit an inquiry through our contact form.