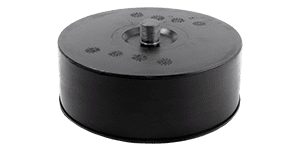

Train Bumper | Rubber to Metal Bonding

Natural Rubber Train Bumper made from rubber to metal bonding.

- Product: Train Bumper

- Process: Rubber to Metal Bonding

- Material: Standard SBR Natural Rubber

- Highlights: Rubber to Steel Insert

The Custom SBR Rubber Molding Experts

Chemical Designation: Styrene Butadiene, Buna S, GRS

Molded SBR rubber is an economical substitute for Natural Rubber in many applications, offering significant cost savings. SBR is an excellent choice for applications where the finished product will be exposed to acids, organic salts, and alkalis. Additionally, SBR rubber is soft and has good flexing characteristics at low temperatures, similar to Natural Rubber. It is wear-resistant and non-toxic.

However, SBR rubber should not be used in applications involving petroleum derivatives or exposure to certain chemicals. Special formulations of SBR can provide resistance to sunlight and heat.

Red SBR rubber is popular for use as a gasket in low-pressure applications, such as washers and gaskets for heating and plumbing. Black SBR is commonly used in applications where abrasion is a factor. For train bumpers, SBR rubber can provide the necessary durability and flexibility to withstand the demands of railway operations.

Rubber To Metal Bonding

For rubber to metal bonding, both injection molding and transfer molding processes are used to bond rubber to metal. The process depends upon the part application, specifically the use of the finished product. This an ideal process for bonding rubber to metal and plastic parts, an example of such parts would be gears, shafts, rollers, bumpers, and stops in a wide array of sizes and shapes. Additional uses for this process include rubber components bonded to steel, aluminum, brass and plastic.

Our knowledgeable technical staff can assist OEM design engineers with design consulting and selecting the correct rubber compounds. Our team can provide recommendations based on the performance requirements and part application. Our goal, with every project, is to produce uniform, high-quality products as efficiently as possible. We develop customized rubber to metal bonded solutions to meet customer requirements.

Qualiform outperforms all other rubber to metal bonding companies producing the largest, most complex parts in the industry. We offer unparalleled experience in this process and are more than happy to consult on your rubber to metal bonding application.

Materials that can be insert molded, overmolded or rubber to metal bonding of a specific area include: steel, brass, aluminum, alloys, exotics, engineered resins and plastics.

Rubber to metal bonded parts range in size from small inserts to very large components serv. Overmolded rubber metal parts are utilized across a broad range of applications.