Custom Extrusion Services for the Highest Quality Glazing Seals

Are you looking for suppliers of rubber window glazing products for your next project? Qualiform is a leading provider of rubber extrusion services, offering a comprehensive range of rubber window glazing seals for various industries. As a certified manufacturer of custom rubber products, we utilize advanced rubber molding technologies to ensure high-level precision for every project. This enables us to reliably produce the ideal rubber window glazing extrusions for your specific application.

What is Window Glazing?

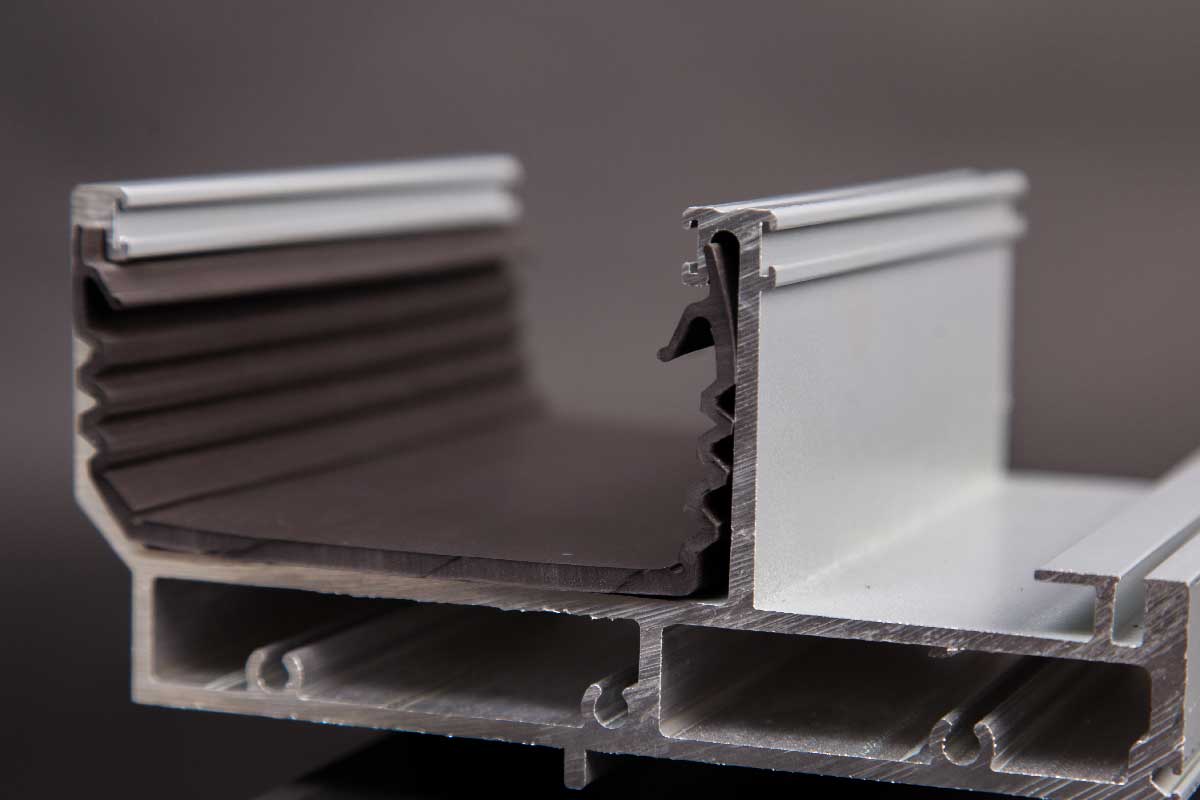

Window glazing is designed to keep air, water, and other fluids from leaking in or out of the window. These are most commonly found in residential and commercial properties as a means of minimizing energy consumption. Rubber window glazing seals are also referred to as weather stripping, window glazing gaskets, window glazing strips, and glazing rubber seal strips. There are also rubber glazing beads, which are much smaller parts while offering similar sealing properties.

is designed to keep air, water, and other fluids from leaking in or out of the window. These are most commonly found in residential and commercial properties as a means of minimizing energy consumption. Rubber window glazing seals are also referred to as weather stripping, window glazing gaskets, window glazing strips, and glazing rubber seal strips. There are also rubber glazing beads, which are much smaller parts while offering similar sealing properties.

Here at Qualiform, we offer more than 50 years of experience in rubber extrusion. So, we can develop custom extrusion profiles to suit your specific window configuration. As a result, the glass will be more secure, and a window rubber seal can provide reliable insulation and waterproofing as well as protection from intense vibrations.

Most importantly, we design our window glazing rubber products to offer high-level performance and resistance in even the harshest environmental conditions. In fact, we carry a full selection of commercial and specification-grade elastomers. So, we can ensure your glazing gaskets, seals, and other parts are tailored to your specific application.

Applications for Rubber Window Glazing

The most common application for window rubber seals is weather stripping and insulation for both residential and commercial windows. However, these seals can also be used to secure windows to doors, cars, trucks, and more! In fact, marine window glazing rubber is a crucial component for boats, as it can prevent severe leaks and flooding.

Some applications of glazing channel rubber seals include:

- Windshields

- Sunroofs

- Drainage Systems

- Boat Hatches

- Fire Protection

- And More!

Additionally, window glazing strips and seals are useful in numerous applications. Many industries depend on these extrusions for their sealing capabilities as well as their superior weather and ozone resistance including construction, transportation, marine, electronics, agriculture, and even aerospace.

How to Choose the Best Glazing Seal for the Job

Getting the best performance window glazing seals means choosing the ideal rubber compound for your application. The difference between a neoprene glazing channel and an EPDM rubber window gasket could significantly impact performance. So, choosing the right compound requires careful consideration of various factors:

- Industry

- Design specifications

- Environmental conditions

- Operating temperature range

- UV and chemical resistance

- Installation methods

For example, EPDM is a uniquely versatile compound used in a variety of rubber beading profile applications. Not only does this compound offer reliable performance for rubber window glazing, but it is also found in vehicles, safety equipment, medical equipment, and more. However, EPDM has extremely poor resistance to oils, gases, and fuels. Therefore, it should not be used for any applications involving those types of substances.

Here at Qualiform, we offer a comprehensive selection of high-quality rubber compounds for our rubber extrusion services to ensure optimal performance in any application.

- Butyl Rubber

- EPDM Rubber

- Natural Rubber

- Neoprene Rubber

- Nitrile Rubber

- Rigid & Flexible

- Synthetic Rubber

- Thermoplastic Elastomers (TPE)

- Viton Rubber

So, how do you know which compound is best for your project? If you are unsure of which compound will provide the performance you need, discuss your options with our technical staff. We are available to answer any questions you have and can provide professional recommendations based on your industry and application.

Why Use Rubber Extrusion for Window Glazing?

There are many reasons to choose rubber extrusion. First, it offers great freedom of design. You can request parts in nearly shape and size, and rubber extrusion companies can use nearly any rubber material. This means that you also have many choices when it comes to the qualities of your parts. Another great benefit of rubber extrusion is that it makes parts that are incredibly strong yet flexible and soft.

If you have any questions about our rubber extrusion services or would like to learn more about rubber window glazing, call us at (330) 336-6777 or submit an inquiry through our contact form.

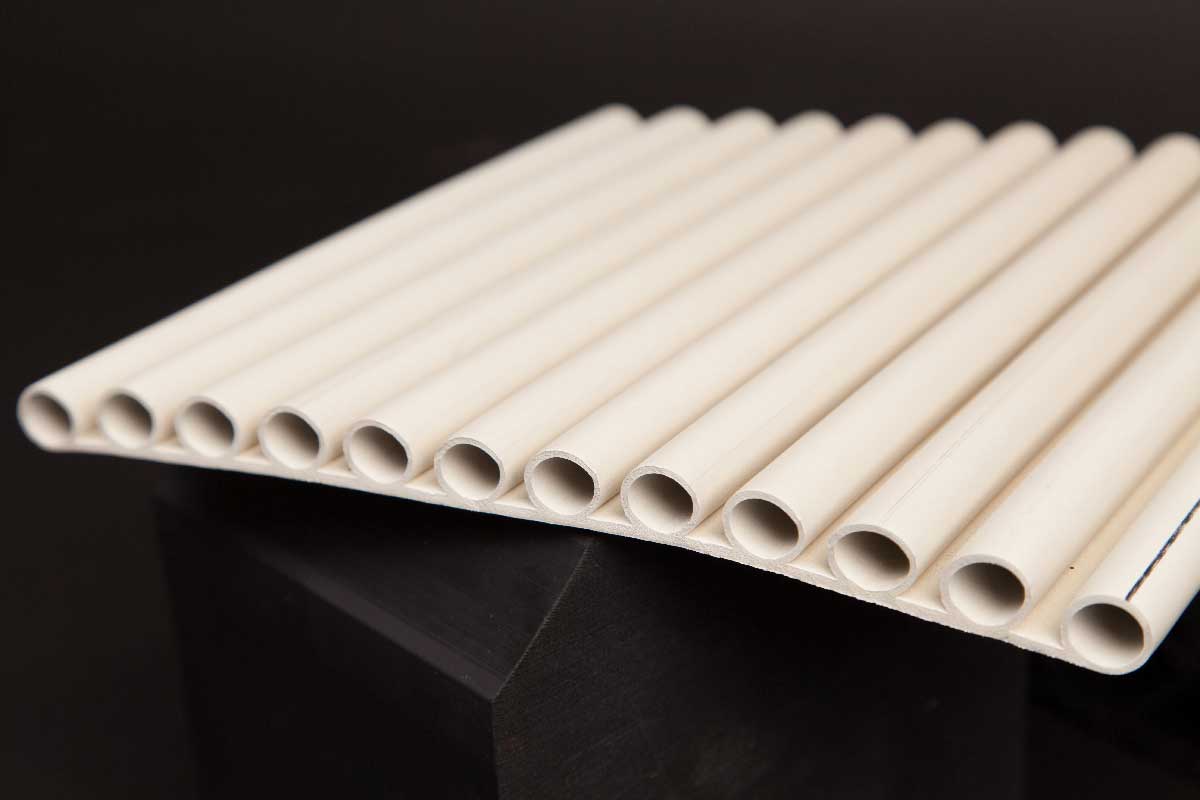

Rubber Extrusion Photo Gallery

Here are some examples of the many different shapes of rubber extrusions we can produce: